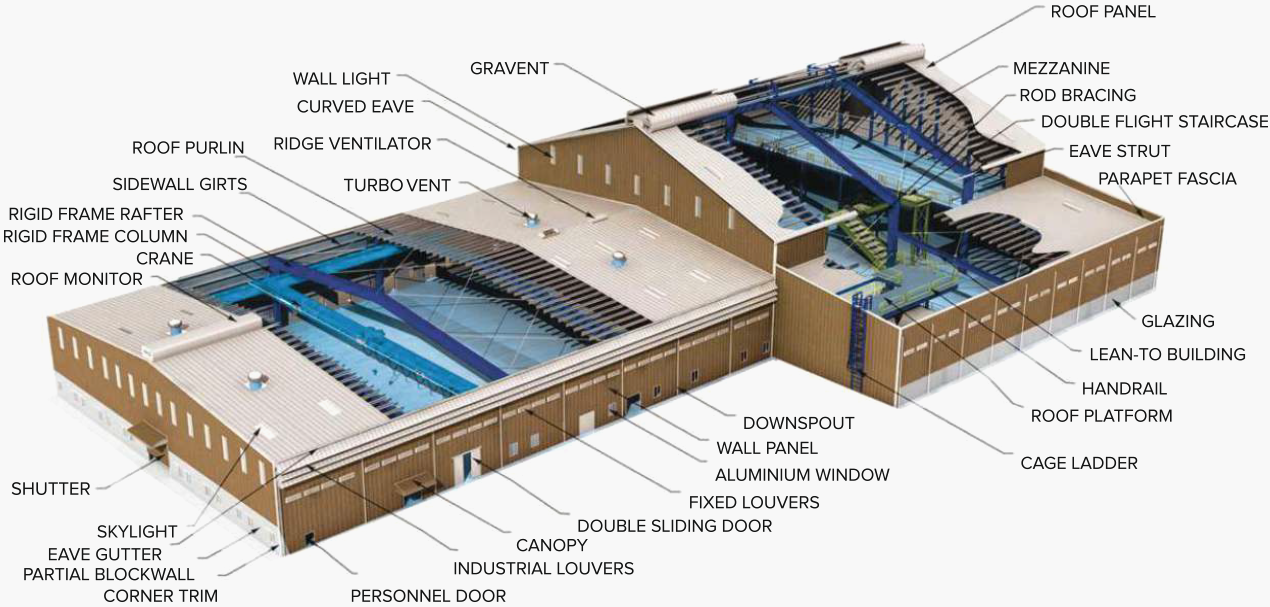

PEB

Applications of PEB

- Factories

- Warehouses

- Workshops

- Offices

- Gas stations

- Vehicle parking sheds

- Schools

- Showrooms

- Aircraft hangers

- Metro stations

- Indoor stadium roofs

- Bridges

- Railway platform shelters

- Outdoor stadium canopies

Comparative Studies

A Pre-Engineered Steel Building (PEB) is made of built-up sections, hot rolled sections and cold-formed elements, which are designed and manufactured at Buildtree’s state-of-the-art factory and then transported to your new Industrial Shed’s site for bolting and erection. We custom design and engineer your Industrial Shed such that you save your cost of civil construction and also begin your operations at the earliest.

| Evaluation Criteria | PEB Building | Concrete Building |

|---|---|---|

| Fabrication | Precise fabrication: Members fabricated in a controlled environment and up to 50% saving in fabrication time on site. | Fabrication done on site; Requires building the reinforcement cage and shuttering work prior to pouring. |

| Delivery and Logistics | Can be delivered in desired sequence anywhere in the world. | Might have to build batch plant on site if site is secluded or huge. |

| Installation Time | Saving in construction time. Fast Installation with no idle time. | 50% Slow and time consuming: The contractor will have to wait for the previous cast to harden (14-28 days) before being able to cast next batch |

| Quality |

|

|

| Cost | Savings of 10%-15% for large span steel building. Gives high return after use. | Construction cost is high at site. No return once destruction. |

| Industrial Applications |

|

Heavy equipment usage such as cranes is limited. |

| Commercial & Infrastructure Applications | Better aesthetics and longer spans can be achieved using steel as building component. | Limited designs are possible with concrete. |